Rope Guide Rails

Rope Guide Rails are a solution that are utilised when there are delicate balustrades made from glass or fragile alloys in place on high-rise buildings. Generally these structures cannot take the loads placed upon them by the rope ‘side loading’ that is caused by industrial abseilers, when performing maintenance works on the building facade. They are not limited to use with glass. Rope Guide Rails are also used on parapet capping where the flashing is at risk of having its waterproofing destroyed; and on exposed slabs that pose dangers of cutting the abseil ropes when under load.

Rope Guide Rail Applications

Unfortunately, rope access solutions are often overlooked and not thoroughly investigated during the architectural design phase. Maintenance is often an afterthought, which can be problematic for rope access work that is critical for ongoing maintenance. In these circumstances, Rope Guide Rails provide the ideal solution. Rope Guide Rails are independent, load-bearing fixtures anchored to the slab that extends past the top of balustrades and other structures to:

- Prevent rope loading.

- Contact with the property.

- Provide safe access.

- Ensure facades, parapets and balustrades do not suffer damage during descents, ascents and work activities.

Glass Balustrade

Alloy Balustrade

Exposed Slab

Capping

Rope Guide Rails are used in a wide range of applications. They provide the ideal rope access solution on buildings with lower level terrace areas, where residents have balconies that protrude past the face of the building’s rooftop, preventing rope access teams from performing a regular descent. The installation of Rope Guide Rails allows technicians to set up their access systems on the rooftop and abseil down the side of the building and over the balustrade, that is then protected by the installed Rope Guide Rail. The alternative is to have workers trudging access gear through individual apartments to set up systems on their balconies, which is typically a cause of concern for residents.

Hi-Rise Rope Guide Rail Systems

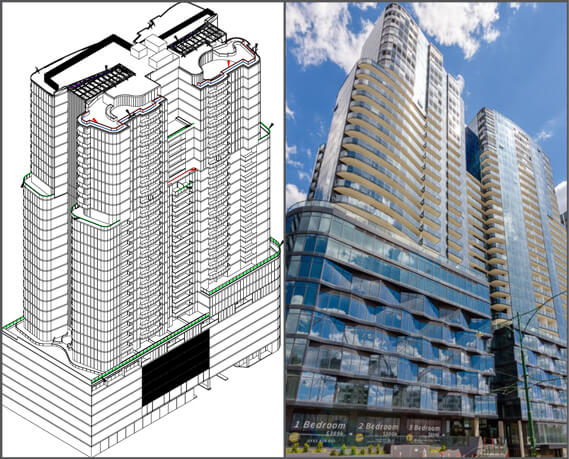

At Hi-Rise, our Rope Guide Rail Systems are custom engineered. Being designed and modelled in 3D CAD, this allows us to validate that they meet client expectations for each site, before fabrication in our factory in Melbourne.

On a recent project, Hi-Rise installed over 200 metres of Rope Guide Rail to the Panorama residential and commercial complex at the heart of Box Hill in Victoria, along with RoofJockeys™, davits, anchors and lifeline systems. This provided a complete rope access solution, allowing safe access to the entire building from top to bottom, without intruding into residential or commercial spaces.

The Rope Guide Rails were powder-coated to match the facade and sit just above and in front of the glass, lining up with existing mullions or gaps to blend seamlessly into the architectural aesthetics of the structure. The system includes karabiner anchorage connections that are welded to various vantage points along the guide rail, allowing technicians to abseil over the curved rail without the risk of rope slippage along the bar.

Green highlighted areas in illustration indicate Rope Guide Rails installed onto the Panorama complex.

Custom designed Hi-Rise Rope Guide Rails on the Panorama complex.

Reach out to a Hi-Rise Specialist for more information on our custom designed, engineered and fabricated Rope Guide Rail Systems for

your project